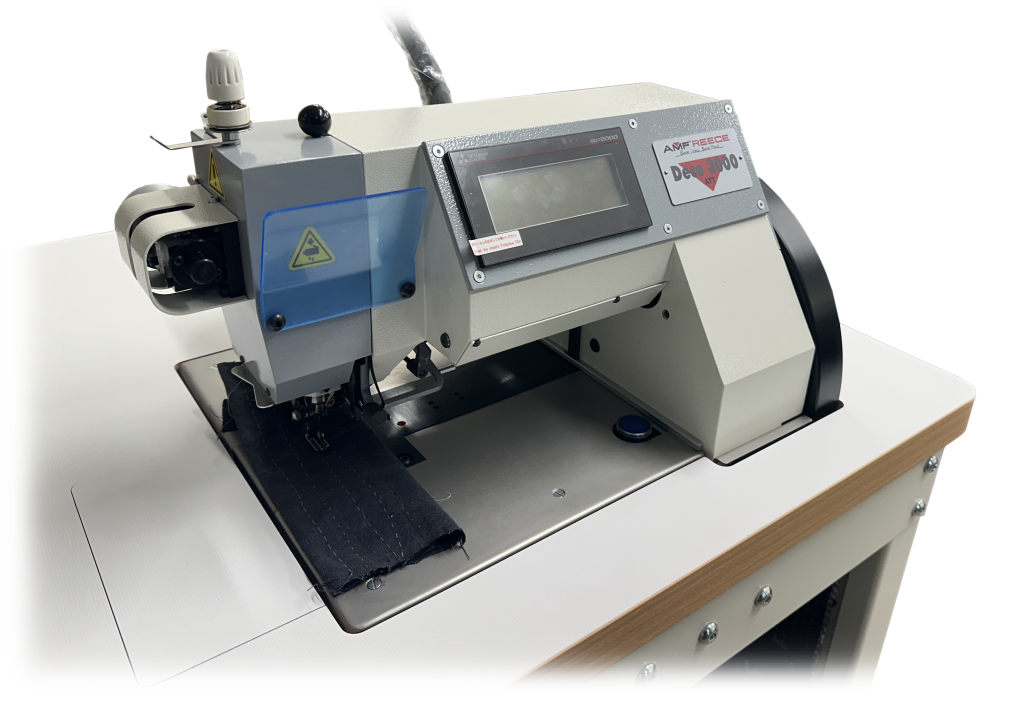

DECO 3000 ATT

- AMF Reece patented floating needle technology, imitation handstitch

- designed for garments of the highest quality

- thread length up to 140cm depending on thread quality and material

- machine control via touch panel

- made in Czech Republic

AMF Reece pioneered template stitching in the 1960s, and the Autojig system remains the unchallenged world leader for assembling garment components ranging in size from pocket flaps to topcoat foreparts. The Autotrack is a Special device for manufacturing your own stitching templates for AMF Reece Autojig machines.

Main features

Floating Needle System was developed by AMF Reece to produce a “true hand stitch”. The machine uses a double pointed needle which has an eye in the middle. By the use of two needle bars, one above and one below the work plate, a length of thread is passed through the material duplicating the hand stitch with flawless consistency and incomparable speed.

Other machines of this type, compared to the Deco 3000, use a single needle bar and an “open eye hook” type of needle. This type of needle makes larger penetration in the fabric, which can cause damage to lighter and more delicate fabrics by snagging the fabric. Our machine, Deco 3000, is the only real Imitation Hand Stitch machine ensuring consistent quality on all types of fabrics.

AMF Reece – Cars offers different sizes of floating needles to insure high quality performance on different types of materials. It is necessary to use different needle bar kits for specific needles.

Any type of stitches can be reversed by a simple touch of a button placed on the work desk, at any speed and time during the sewing cycle (e.g. at the jacket lapel break point). This increases productivity and minimizes thread waste.

It is no longer necessary to do separate bar tacking operations. To secure the beginning and end of the stitching the operator can take the advantage of condensed stitching or backtacking functions. Both are easily activated by a special pedal and the stitching parameters are set on the touch screen display. As standard the machine is already equipped with the condensed stitching function. The backtacking function is available optionally.

High Sewing Speed up to 500 spm makes the Deco 3000 ten times more productive than hand sewers, providing ensuring consistent quality.

The display provides the operator with a user-friendly working environment. All operations such as stitch type, sewing speed, stitch length and thread trimming time etc., are performed using easily understood symbols, which require no language translation.

High and consistent quality on all types of fabric is assured by using the double pointed needle, which is passed through the fabric between opposed needle bars. Other machines of this type have a single needle bar and an “open eye hook” needle. This can cause problems in more delicate fabrics by snagging the fibers. The Deco 3000 machine is the only “Real Imitation Hand Stitching Machine” available.

Type of stitching can be easily selected by a simple touch of the screen, ranging from a pick stitch, saddle stitch to various style stitches (long and short variations), for which the length of the stitch can be precisely specified.

Unique customized decorative style stitching can be easily adjusted on the touch screen, in addition to the pick stitch, saddle stitch and long/short variations. Each custom stitch pattern comprises of a sequence of 10 different upper and 10 different lower stitch lengths.

Either standard polyester/nylon cone or pre-cut waxed silk thread can be used depending on the machine modification and application. The use of the standard thread eliminates color matching issues; threads are available in a wider range of sizes and can be also employed in other garment applications. Nevertheless, when sewing the true “pick stitch”, it is necessary to use the pre-cut waxed silk thread which is specially twisted to give the hand stitch appearance. The pre-cut waxed silk threads are available in various colors and sizes and can be ordered through our Spare Parts Department.

This special gauge ensures straight stitching along the material edge. It is especially recommended when sewing to the material edge, for example with the pick stitch application on men´s jackets. The minimum distance from the garment edge is 1mm.

New design of the throat plate and the clamp feet improves the needle guidance and minimizes the skip stitching. It also significantly helps to sew the stitches more close to the material edge.

Thanks to the new design of the bedplate, the maintenance of the sewing are is now very comfortable. The operator can very easily pull off the magnetic left bended throat plate from the machine and entre the sewing area if needed.