EBS Mark II

– Electronic Button Sewing and Wrapping Machine

- AMF Reece patented floating needle technology, imitation handstitch

- button sewing and wrapping machine in one

- machine control via touch panel

- made in Czech Republic

The EBS Mark II, electronic button sewing and wrapping machine, duplicates the quality of hand sewn buttons with the AMF Reece unique floating needle technology. The electronic button sewing and wrapping machine has been developed hand-in-hand with Italian producers of top quality high-end suits. It performs a neatly sewn button that stands away from the jacket front with a tightly wrapped shank and no unsightly thread showing on the underside of the garment. The electronic button sewing and wrapping machine can handle wide range of buttons ranging from shank buttons to 2, 3, 4-hole sew-through buttons. It sews with standard polyester cone threads. All sewing parameters such as electronically controlled thread tension, neck height, stitch depth, different sewing speeds for individual sewing phases, button stitching options – “blind”, “show” stitch or “V” shape stitching are simply set on a large colored touch screen display. Due to the hand-sewn effect the button sewing and wrapping machine is presented as the hallmark of quality and is required especially by manufacturers sewing top quality garments.

Main features

Unique technology patented by AMF Reece. Double pointed needle with an eye in the middle is passed through the fabric between two needle bars to perform “true“ hand stitching. In replication to a seamstress a length of thread is passed through the material duplicating the hand stitch with flawless consistency and incomparable speed.

The combination of 7 independent motors enable the machine to sew a wide range of buttons and styles, along with an incomparable sewing quality. The main drive is controlled by the servo motor while the X-Y movements for the button stitching and wrapping are driven by step motors. The step motors are also used for button feeding, thread tension, neck height and stitch depth adjustments.

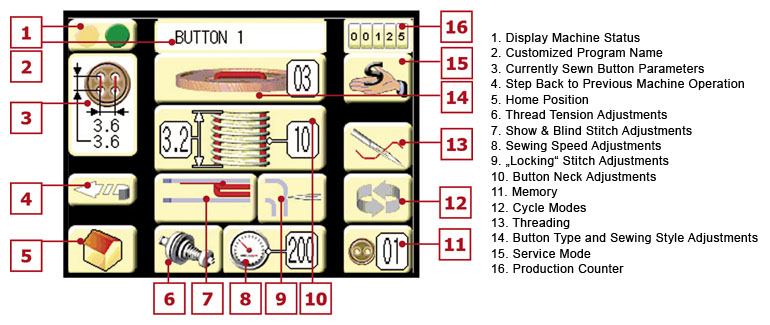

5,7” LCD high resolution full-color touch screen display incorporates new sewing functions. The use of easily understood symbols makes the machine very easy to operate with minimal training time. User friendly icons are used for setting parameters such as button type, sewing style, number of stitches and wraps, neck height and stitch depth. Currently sewn button parameters are displayed on the main screen while sewing.

The step motor controlling the thread tension ensures smooth distribution of pre-set tensions. The thread tension can be separately programmed for four different sewing phases such as stitching the button, show stitch, neck wrapping and the final ”locking“ stitch. This plays an important role especially when sewing on difficult and thin materials to eliminate puckering and other sewing issues.

The sewing speed can be adjusted from 100 to 200 spm from the touch screen display. To achieve top sewing quality, different speeds can be separately programmed for button stitching, button wrapping and final ″locking“ stitch.

A lower speed of a final stitch can be required for example when sewing with thinner threads.

The machine offers two different cycle modes – standard and prompt. The standard cycle mode can accommodate up to 20 different button styles within one program. The prompt cycle mode is designed only for two different button styles, for example when sewing one button with blind stitch and two with show stitch on jacket. In the prompt cycle mode the required button style is activated by the pedal. The operator can pre-set 20 standard and 20 prompt cycle mode programs.

Machine is standardly equipped with sewing and marking lights. The sewing light is embedded in the sewing head and illuminates the sewing area much better than commonly used work lights. The red LED marking light ensures easy placement of the garment and marks the exact button position.

Especially small scale companies, that are frequently changing production range, would appreciate our new multi-threading system fixed on the top of the sewing head. This flexible system allows the operator easy and quick change between sewing threads. Operator can thread the multi-threading system with up to 5 different threads (size, type, color) that are always ready to be used for sewing.

A pneumatic system guarantees easy threading by bringing the thread from the multi-threading device to the needle eye. The needle threading itself is ensured by a threading hook. Our new threading solution provides the operator with maximum comfort, reduces threading time and eliminates complicated and time consuming manual handling.

Compared to the former model which only sewed with special waxed threads, the new machine can handle standard polyester cone threads size 30, 40, 50, 70. This helps to eliminate color matching issues and reduces thread costs. Thanks to a newly developed trimming mechanism, the cone thread is trimmed automatically. In addition the special waxed Rice threads can be used in size 3, 4, and 5.

A pneumatic system guarantees easy threading by bringing the thread from the multi-threading device to the needle eye. The needle threading itself is ensured by a threading hook. Our new threading solution provides the operator with maximum comfort, reduces threading time and eliminates complicated and time consuming manual handling.

The EBS Mark II machine has a specially designed ergonomic table equipped with an additional lower-level desk for easy placement of the sewn garment. The lower-level desk and the sewing table itself can be adjusted for operator comfort.

The machine is designed to meet the highest safety requirements from the European Union. The standard fitted automatic sliding eye guard protects the operator during sewing. The emergency stop button, placed on the operator’s right hand, is ready to be used if needed (for example in case of thread or needle breakage). Hand start control is used to activate the machine to minimize the risk of the accident at start of the machine. Machine can be activated only when all sewing mechanisms are in their correct position. In case of any machine error the operator is provided with basic instructions that appear on the machine display to eliminate the problem.

Button type range from 2, 3, 4-hole sew-through buttons to shank buttons in different sizes are easily programmable from the touch screen. At the time of button specification, the operator selects all the sewing style with one simple touch. Up to 99 different button style combinations can be stored in the machine memory.

Sewing range and style

Button type range from 2, 3, 4-hole sew-through buttons to shank buttons in different sizes are easily programmable from the touch screen. At the time of button specification, the operator selects all the sewing style with one simple touch. Up to 99 different button style combinations can be stored in the machine memory.

The EBS Mark II machine has an option called “blind” or “show” stitch in addittion to standard. If the show stitch option is selected, one single stitch is passed through the garment for high-quality appearance. Alternatively, the blind stitch does not show on the inside of the garment and the thread only penetrates to the middle of the material.

Optional “V” shape stitching method is available for 4-hole sewn-through buttons. When attaching the button, all stitches are sewn into one preset location. Furthermore, combining the “V” shape sewing with the blind stitching would enhance the stitching quality, which will give the hallmark of quality to the sewn garment.

Buttons are proportionally and automatically wrapped to form a firm button neck. Operator can specify number of wraps, neck height, start and end of wrapping position. Depending on the designer‘s requirements, the neck height can be programmed from 0-8 mm.

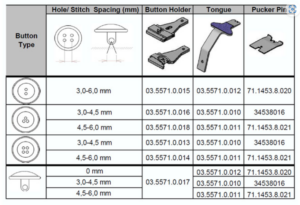

The EBS Mark II machine is supplied with 5 exchangeable button holders that cover all button applications. Thanks to flexible pins that adjust automatically, one holder can accommodate different button sizes. Unlike other machines on the market, the holder does not need to be changed for different button sizes. The feeding speed of a button loader can be adjusted directly from the touch screen display for different button types.

A lower speed of a final stitch can be required for example when sewing with thinner threads.

Special new design of the tongue ensures perfect feeding and fixing of the fabric. The tongue automatically adjusts to different material thickness and tightly holds the sewn garment while stitching the button. The new design also simplifies the tongue change for 2, 4-hole sewn through and shank button.

Preventing the button from unraveling or falling off, the machine has an option to secure the first and last stitches. If required, the button can be locked on with up to 3 stitches before attaching the button and also after wrapping it by passing the thread through the middle of the neck.

Machine duplicates the continuous thread of a tailor‘s hand stitching, therefore when sewing 4-hole buttons, cross-over thread is not needed. Other machines on the market either require the cross -over stitch or perform the button sewing in more sequences. Thanks to the floating needle technology, the EBS Mark II machine attaches the button in one continuous operation.

A pneumatic system guarantees easy threading by bringing the thread from the multi-threading device to the needle eye. The needle threading itself is ensured by a threading hook. Our new threading solution provides the operator with maximum comfort, reduces threading time and eliminates complicated and time consuming manual handling.

Standard accessories

The EBS Mark II machine is supplied with exchangeable button holders that cover all button applications. Thanks to flexible pins that adjust automatically, one holder can accommodate different button sizes.

When changing between button styles, for example from 2 to 4-hole button, it is necessary to use proper button holder, pucker pin and tongue extension. All parts are supplied with the machine in the standard accessories as shown in the conversion list below.